High Viscosity Ketonic Resin

Price 155 INR/ Kilograms

High Viscosity Ketonic Resin Specification

- Type

- Ketonic Resin

- Grade

- Industrial Grade

- Application

- Flexographic Inks, Gravure Inks, Lamination Inks

- Color

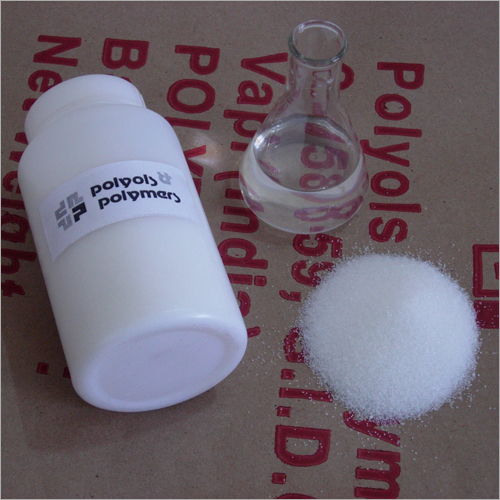

- White

High Viscosity Ketonic Resin Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Supply Ability

- 25 Kilograms Per Day

- Delivery Time

- 2-3 Days

- Sample Available

- No

- Packaging Details

- Poly Bag

- Main Export Market(s)

- Australia, South America, Middle East, Africa, Western Europe, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

About High Viscosity Ketonic Resin

| HIGH MELTING & VISCOSITY | | |

| | POLYTONETM K 96 | POLYTONETM K 97 |

| Physical Form | Pear Shaped Granules | Pear Shaped Granules |

| Melting Point (Capillary) | 105 110oC | 110 120oC |

| Viscosity (B4 Ford Cup @ 25oC) | 20 23 Sec (50% Soln in Spirit) | 22 25 Sec (50% Soln in Spirit) |

| Hydroxyl Value (mg KOH/gm Resin) | 230 250 | 230 250 |

| Acid Value (mg KOH/gm Resin) | 0.5 | 0.5 % |

| Characteristics | Hardness Excellent Thixotropic Properties Suitable for Ball Point Pen Ink Quick Drying | Hardness Excellent Thixotropic Properties Suitable for Ball Point Pen Ink Quick Drying |

POLYTONE K 94/95/96/97/HH Resins are neutral, unsaponifiable, cyclohexanone aldehyde resins of exceptional lightness in color and light fastness. Its is a condensation product of cyclohexanone and formaldehyde to give a solid product, which includes carbonyl and hydroxyl groups Its wide compatibility and good solubility cause it to be used in most diverse coating systems to enhance drying properties, harness, gloss and adhesion as well as solid content. It displays good pigment-wetting properties, and increases yield of coating systems. It is suitable for all types of industries, including nitrocellulose paints where it improves polishing characteristic and adhesion. In printing inks, it enhances adhesion, imparts gloss, improves drying properties, and increases solids content, where it is used in maleic resins, alkyd resins, nitro cellulose, and polyvinyl butyral.

Applications

- Inks & Paints: Flexographic & gravure ink formulations, lamination inks, lacquers and paper inks, nitrocellulose paints, varnishes, heat seal coatings.

- Coatings : Heat-Seal Coatings, primer and base coatings, gasoline resistant coatings & nail lacquers, Vinyl Sealers, Vinyl Coatings, It can be called as excellent multifunctional coating additive.

- Ketonic resin is useful in the manufacture of PVC lacquers and finishes for the surface treatment of wooden furniture and articles

- This resin finds its major use in ball pen inks and calendar inks

- It can also used in isocyanate based adhesive systems, PU Systems as well as radiation cured adhesives and in water clear systems

Optimized for Modern Ink Applications

The High Viscosity Ketonic Resin stands out for its compatibility with flexographic, gravure, and lamination inks. Its high viscosity ensures improved ink transfer and consistent print quality, making it a preferred choice for industrial use. Suitable for diverse printing substrates, it delivers excellent performance and durability in every application.

Reliable Manufacturing and Distribution in India

As a premium white, industrial-grade ketonic resin, our product is manufactured and distributed by established suppliers across India. Our proven logistics network ensures prompt and efficient supply, catering to both large-scale and niche requirements. Count on us for technical support and seamless product delivery.

FAQs of High Viscosity Ketonic Resin:

Q: How is High Viscosity Ketonic Resin used in flexographic, gravure, and lamination inks?

A: This resin serves as a key binder component, improving ink adhesion to substrates, enhancing gloss, and providing stability during the printing process, making it highly effective for flexographic, gravure, and lamination ink formulations.Q: What benefits does high viscosity offer in ketonic resins for ink manufacturing?

A: High viscosity in ketonic resin enhances the body and flow of the ink, allowing for better pigment dispersion, improved print definition, and increased resistance to smudging, all critical properties for high-quality printing.Q: Where can I purchase industrial grade High Viscosity Ketonic Resin in India?

A: You can acquire this high-quality resin through authorized distributors, manufacturers, and suppliers spread across India, ensuring genuine products with reliable technical support.Q: When should I consider using High Viscosity Ketonic Resin in ink applications?

A: It is advisable to use this resin when you require excellent adhesion, high gloss, and stability in your printing inks, particularly for demanding flexographic, gravure, or lamination processes.Q: What is the process of incorporating Ketonic Resin into ink formulations?

A: Incorporation generally involves dissolving the resin in suitable solvents under controlled temperatures and blending it with other ink ingredients to achieve the desired viscosity and performance characteristics.Q: How does this resin ensure quality and consistency in printing results?

A: Its industrial-grade formulation ensures consistent particle size and purity, contributing to stable ink formulations and predictable, uniform printing performance across batches.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyketone Resin Category

Cyclohexanone Formaldehyde Resin

Price 155 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Application : Coating Compositions Containing Cellulose Esters

Grade : Industrial Grade

Type : Other

Color : White

Standard Polyketone Resin

Price 155 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Application : For Industrial Use

Grade : Industrial Grade

Type : Polyketone Resin, Other

Color : White

Regular Ketone Resin

Price 155 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Application : Manufacture of PVC Lacquers

Grade : Industrial Grade

Type : Ketone Resin, Other

Color : White

Low Viscosity Ketonic Resin

Price 155 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Application : For Industrial Use

Grade : Industrial Grade

Type : Ketonic Resin, Other

Color : White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free